The 3D printing of a metal part without adequate knowledge of the design process has been a tedious trial-and-error process for those without the necessary skills, which often leads to unsuccessful and expensive debinding and sintering outcomes.

But now, industrial experts from Raise3D possess the advanced know-how needed for metal part optimization, ensuring that customers’ printed parts are of the highest quality, with safe, efficient, and guaranteed debinding and sintering results.

Raise3D’s industrial business manager, Marco Sena, explains in detail what customers should be aware of when considering metal 3D printing and how the Raise3D First Metal Print service contributes to expertly crafted metal parts with guaranteed results. At the start of this initiative, Raise3D will offer the service in Europe, with other regions of the world to follow at a later date.

What is Metal FFF 3D printing?

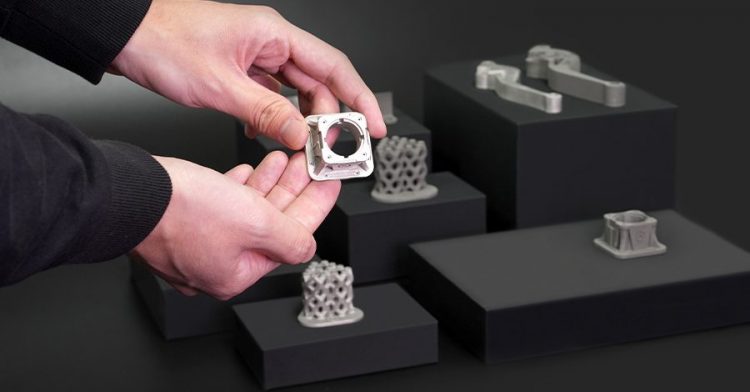

Metal Fused Filament Fabrication (FFF) is an indirect, accessible, and user-friendly process for 3D printing metal objects. It follows the same basis as the metal injection molding (MIM) process, where it is necessary to undergo a three-step process that consists of 3D printing, debinding, and sintering to achieve the final result.

Common challenges that arise during the metal FFF printing process

Model optimization can be challenging because it needs to take into account process-specific requirements from debinding and sintering. Factors such as print orientation, support structures, and design guidelines can have a significant impact on print quality and the overall success rate of the full process.

Level of expertise required to successfully 3D print metal parts on the Forge1

Forge1, in combination with our dedicated slicer, ideaMaker for Metal, provides users with a seamless user-friendly way to achieve perfectly printed green parts, with little need to learn more than what you would need to know to 3D-print a plastic part.

Getting started with metal FFF 3D printing

To get started, our Forge1 3D printer is the only thing you need. In addition to being quite easy to set up and already being optimized for metal FFF printing, it also comes with dedicated slicer software, accessories and two spools of BASF Ultrafuse Metal filaments to start your prints without great obstacles.

Types of metal materials that can be 3D printed on the Forge1

Raise3D cooperated closely with BASF AM Forward, and the Forge1 is optimized to use their Ultrafuse® Metal Filaments. Currently, it is possible to print with two grades of stainless steel, 316L and 17-4 PH. Since the printer is equipped with a dual nozzle head, it is also possible to use Ultrafuse Support Layer. Although not suitable to print standalone parts, this material is a game-changer as it can be used as an interface between the support structure and the object, creating a barrier during sintering that makes the separation of the supports from the sintered metal part after the process exponentially easier.

Design requirements and limitations for 3D printing metal parts on the Forge1

The application of DfAM (Design for Additive Manufacturing) is a major factor regarding the success of a 3D-printed metal part in all processes, with metal FFF being no exception. The Forge1 will be very helpful for customers who wish to print with the best process and parameters. However, without specific design knowledge for the entire process, achieving a successfully debinded and sintered part might become a long, tedious and possibly expensive trial-and-error process. Raise3D’s First Metal Print Service was designed specifically for this, allowing Raise3D’s specialists to aid our customers with this knowledge, skipping the trial-and-error phase and leading them straight to the creation of a flawless metal part.

Raise3D First Metal Print service, how it works, and how it solves common challenges

Raise3D First Metal Print Service is a service where a team of experts from Raise3D validates our customers’ parts prior to printing and provides them with the optimized instructions and the best printing recipe possible to reach a successful metal part. This service ensures that customers will get a high-quality metal part with no issues. If design guidelines and Raise3D’s instructions are followed, customers can trust that they will get the results they want. In the event that there are any issues, we offer a money-back guarantee to ensure complete customer satisfaction.

To learn more about the Raise3D First Metal Print service, please visit this page or contact us directly at metalprint@raise3d.eu.